| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

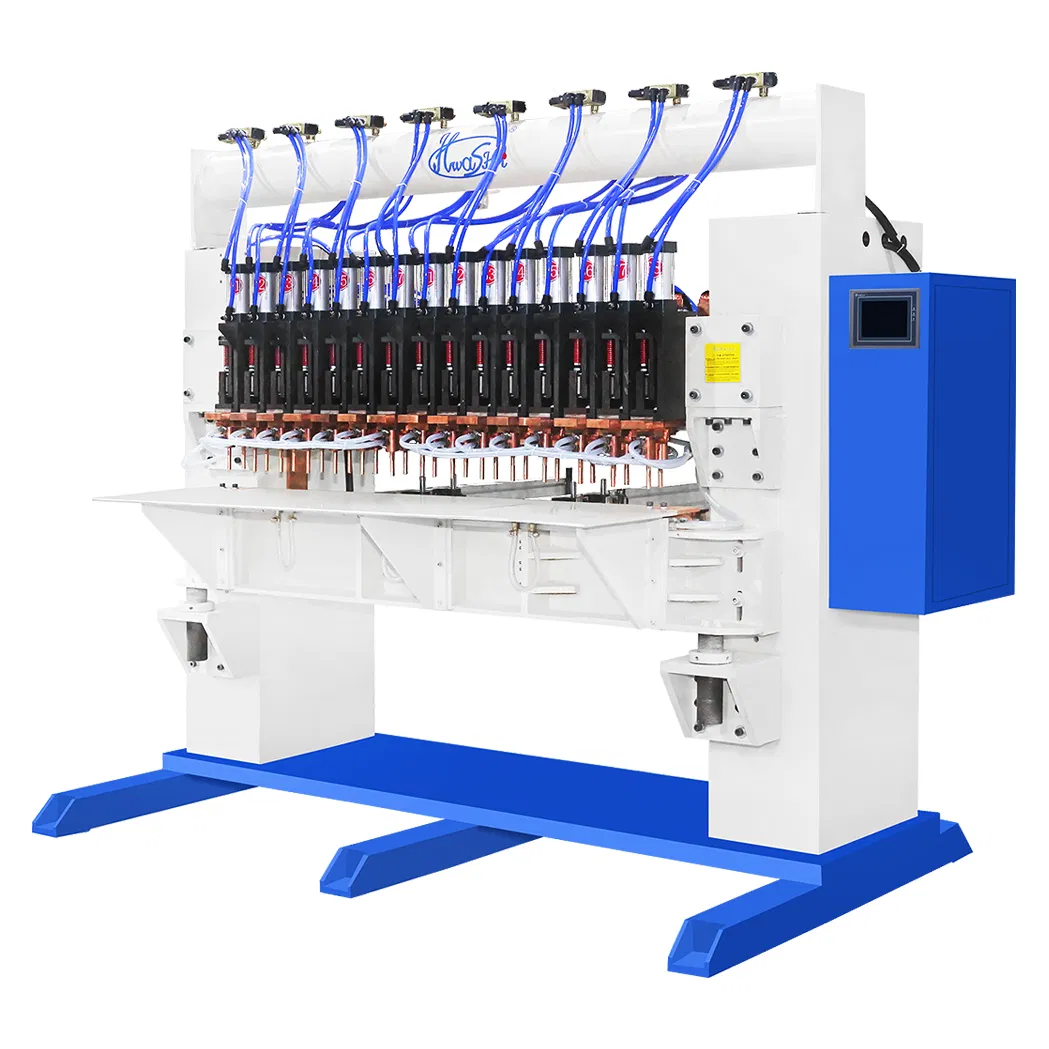

Brand Name : hwashi

Model Number : WL-SQ100K

Certification : CE/CCC/ISO

Place of Origin : China

MOQ : 1 set

Price : negotiation

Payment Terms : L/C, T/T

Supply Ability : 50 sets per month

Delivery Time : 60 working days after received your payment

Packaging Details : sea worthy wooden package

Model : WL-SQ100K

Conductive Way : Both-Sided

Rated Capacity : 160kVA X2

Applicable Material : Stainless Steel, Carbon steel, Aluminum, Metal

Welding Method : Resistance Touch Welding

Max.Welding Thickness : 2+2mm

Warranty : 1 years